HEAT AND ELECTRICITY TO HELSINGE.

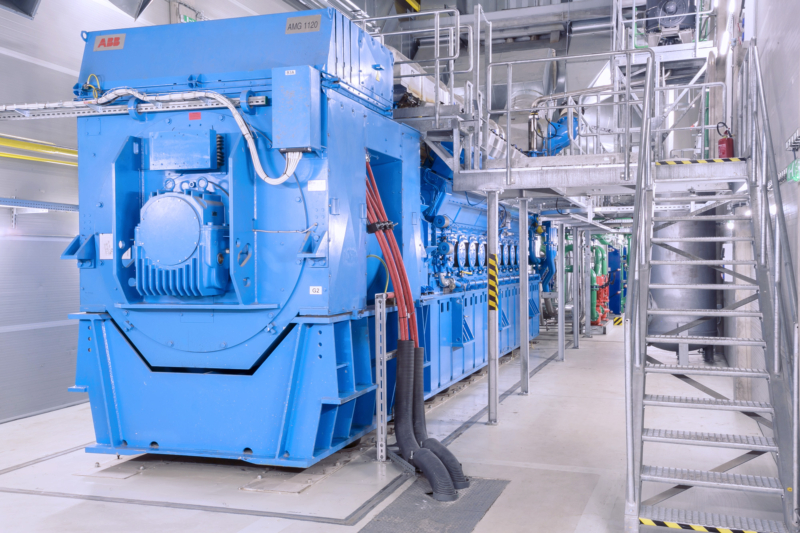

The 20-cylinder B35:40V20AG lean-burn unit installed in Helsinge, north of Copenhagen, was the first 20-cylinder plant to become fully operational.

Who: Helsinge Fjernvarme

What: 1 x B35:40V20AG natural gas engine delivering 8500 kWe and 9510 kWt

Where: Helsinge, Denmark

The power plant operates in CHP mode and provides heat to 1,400 local homes, with excess electricity sold to the national grid. As an extension to its popular forerunner, the K-gas series, the larger 20-cylinder B-gas engine is a medium speed, spark ignited, lean-burn unit producing 8.5 MW of electrical power. Although it is also available in 12 and 16 cylinder versions, it was chosen by the municipality of Helsinge in its largest format. A key design philosophy for the B-gas engine was dictated by the need for lower exhaust emissions and high electrical and heat recovery efficiency and reliability.

At Helsinge, where the power station has been given a sleek, ultra modern exterior, the B-gas engine is achieving measured efficiency figures of 45.5% (47.7% according to ISO 3046-1), which is 1.3% higher than the figure originally guaranteed by Bergen Engines upon delivery in 2006. All of the heat produced is used within local housing and industry. Because the Helsinge plant is non-profit-making, the excess electricity produced is fed into the grid and the profits made from that are used to reduce the price of the heat charged to the local community.

The first B35:40V20 medium-speed natural gas engine from Bergen Engines became operational at the power plant in Helsinge, in 2006.

The station also retains the service of its original pair of 18 cylinder K-gas engines, which each have a mechanical output of 3,06 MW and are used for standby duty should the need arise. The 20-cylinder engine is only run to feed electricity into the grid when the price of electricity merits it. However, as electricity prices are monitored hourly by Helsinge, this can sometimes mean that the engine may be turned on and off up to three times daily. For example, on a Saturday when most industry is not working and there is little demand for electricity and the price is low, the engine is not used. But when it runs three times a day it is a stern test of the quality of the engine and a test which it passes successfully.

Get in touch

Want to know more about how we can empower your business? Visit our ‘Contact’ page to speak directly with our team or send us a message here and one of our specialists will get in touch soon.