Upgrades

SCROLL TO EXPLORE

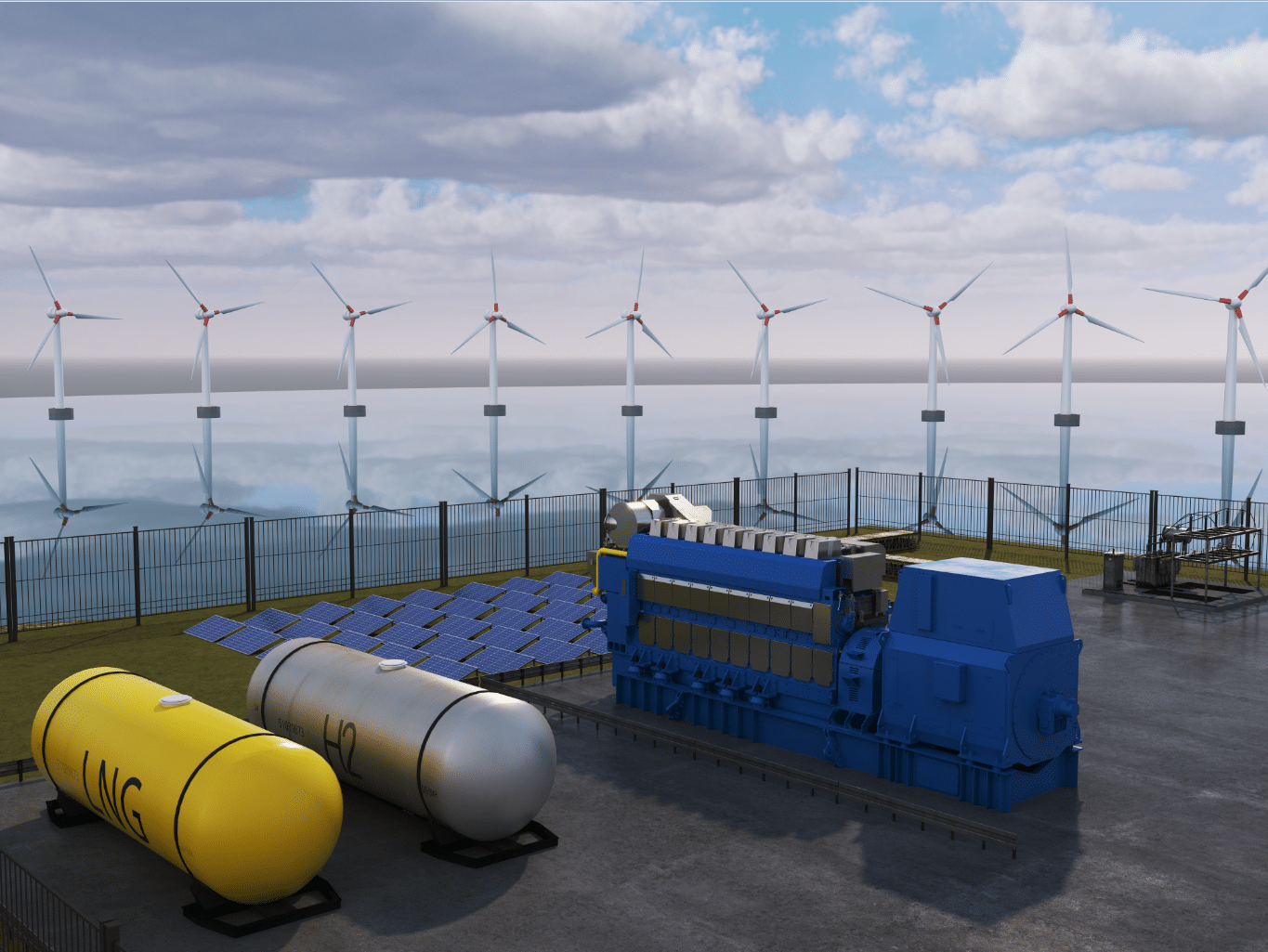

Do you want to improve the performance of your equipment or reduce emissions? We have a series of cost-effective upgrades available that will make sure your engines are up to date with respect to performance and operational safety.

Some of our upgrades are specifically developed to minimize the environmental footprint and will ensure that your business remains compliant with national emission regulations over time.

Our engines are designed to remain in service for several decades. During that time there will be changes in product design and technology. Upgrading and using the correct OEM (Original Equipment Manufacturer) replacement parts can pay dividends in plant performance and fuel savings.

Learn more about some of our upgrades here:

-

-

Redundant autostop

-

NOx control

-

Methane slip reduction

-

Knock detection

-

Ignition system upgrade

-

Fast Ramp-up Mode

-

Exhaust Preventilation

-

Equipment Health Monitoring

-

Cylinder Pressure Monitoring

Other Services

Swipe to see all services

ON LAND.

Bergen engines are principally found driving alternators in power generation applications, either singularly or in multiples up to 200MW, with 300MW currently under construction. Our engines and generator sets are widely recognised by operators worldwide due to their proven technology, robust design, and low operating costs.

AT SEA.

Bergen engines power generators for offshore oil & gas installations and on board a wide range of ocean-going vessels. Bergen engines can also be found in direct propulsion applications. From tugs and fishing vessels, to ferries, offshore supply and cruise ships, Bergen engines are a watchword for supreme quality and reliability in the marine industry.

Contact Bergen Engines

Please fill in your contact details below and we’ll reply as soon as we’re able.

Contact Bergen Engines

Looking to connect with our team?

Whether you’re interested in exploring our latest offerings, sourcing spare parts, discovering career opportunities, or engaging with our communications team, you’ve come to the right place!

Simply fill out the form below, and our dedicated team will promptly attend to your request.